MANUFACTURING

CONCEPT 32: manufacturing for the Whole Home Solution

Tucked into the northeast corner of Boulder County, our Longmont manufacturing facility is where your cabinetry comes to life. This isn’t a warehouse or a third-party shop; it’s our own shop, run by our team, built to create custom cabinetry and storage that fits your home perfectly. From kitchens and bathrooms to closets and whole-home storage, everything we build starts right here.

We use advanced machinery and smart manufacturing software to ensure exceptional accuracy, consistency, and finish quality but technology is only part of the story. What truly matters is how it benefits you: tighter tolerances, smoother drawer action, cleaner lines, and cabinetry that fits exactly the way it’s supposed to. No filler panels where they don’t belong. No “close enough.”

Open Concept Kitchen Remodel done with FENIX surfaces utilizing Zero Edge Technology - 43 Beaver Way, Boulder, Colorado

Every project we make is custom designed for your space, your lifestyle, and your taste. Our shop combines precision equipment, like computerized saws and machining centers, with experienced craftspeople who know how cabinetry should feel, function, and last. This balance allows us to deliver beautiful results efficiently, without sacrificing attention to detail.

We also follow a LEAN manufacturing philosophy, which means we’re thoughtful about how we work. We minimize waste, streamline processes, and stay organized. This results in better quality control, faster turnaround times, and a more responsible use of materials. It’s good for your project, it’s good for the environment, and it's good for Colorado.

We invite you to visit our showroom and tour the facility to see the process firsthand. You’ll get a behind-the-scenes look at how your cabinets are built and the materials and hardware we use every day. Explore our finishes, colors, and hardware options to see what makes Concept 32 / Closet & Storage Concepts different and why where your cabinets are made truly matters.

Visit the Materials page and Hardware page to learn more about the types of products we use in our shop. Review our list of Kronospan finishes and colors.

We strategically selected our manufacturing facilities to service both Boulder County, Weld and Larimer Counties equally. Because of our proximity to Fort Collins, Loveland, Berthoud, Frederick, Firestone, Estes Park, Wellington, Windsor, Timnath, Laporte, Campion and all points in-between, we are able to construct and install your kitchen remodel, closet system and storage cabinets quickly and efficiently with the same level of precision and expertise you expect regardless of type of size of project.

Our service area also includes the Denver - Aurora - Lakewood area and west of the Rockies. Visit our projects page to see custom cabinet work around the state of Colorado. View our Concept 32 brochure then contact us for your free consultation.

Get Your Free Consultation

Enter Your Contact Information

Your email and phone number are used to schedule your free consultation only. Please view our Privacy Policy for more info.

Zero Edge Technology

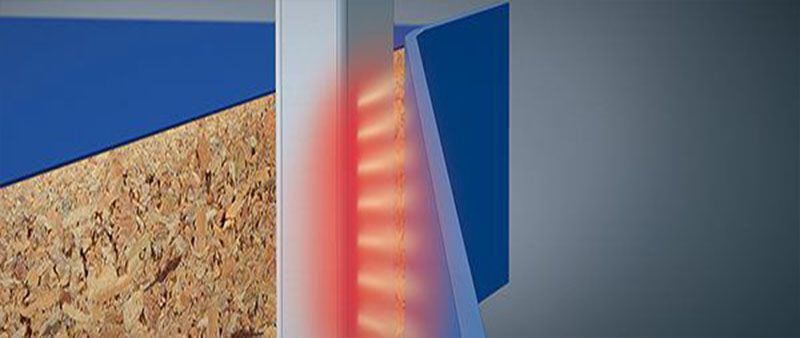

Your Perfect Invisible Joint With HOMAG AirTec

Zero edge is aesthetically pleasing, a stronger and longer-lasting edge, and it offers anti-bacterial benefits that make it a great solution for restaurants, health-care and similar commercial and public uses.

AirTec is the latest technology developed to achieve zero edge edge-banding or invisible glue lines. The machine is a reactivation unit that uses compressed, heated air to activate the adhesive or active layer. With this technology, air is propelled through a nozzle as the edge-banding material travels through the magazine, fusing the material to the panel edge creating an invisible joint.

Millwork today requires precise tolerances to create a finished design with notable benefits. Zero Edge Technology eliminates unsightly seamlines on the edges of cabinets, drawers, and other visible areas, which results in a high-end appearance and creates a beautiful, virtually seamless look for your cabinets and storage systems. These feature precise color matches and an exceptionally tight seal that extends the life of the piece both functionally and aesthetically.

Testimonials

"I just wanted to reach out and let you know how great Minde was on this project."

"Such a professional, talented and kind. He just finished up and it looks really wonderful plus the client is thrilled. THANK YOU!!!!"

- Gala Stude Interiors